Dipl. Ing. Michaela Störkmann, Armacell Technical Manager EMEA

Fabric-covered elastomeric insulation materials have proven themselves as a time- and cost-efficient alternative to the subsequent cladding of technical equipment. Unlike traditional insulation materials and claddings, they can be installed directly in a single work step and allow considerable space savings.

Technical insulation on industrial equipment is usually clad to protect it against mechanical impact, moisture, dirt, oil or production chemicals. In outdoor applications, claddings also protect against UV radiation, weathering and the increased risk of corrosion. They also facilitate cleaning, which is particularly important for equipment in hygiene-critical areas. In the case of exposed services, such as ducts and pipes in open ceiling constructions, claddings improve the aesthetic appearance. Alongside sheet metal, stucco aluminium or PVC foils, alternative solutions made of flexible fabric coverings or rubber have established themselves.

Significant time savings during installation

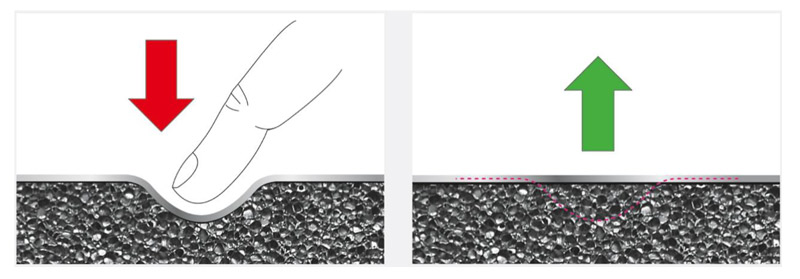

These lightweight products have high mechanical stability whilst still retaining a certain degree of flexibility and they are rot-resistant. The cladding materials protect the insulation against mechanical impact and at the same time are so flexible that they recover from blows, usually leaving no dents in the surface.

Illustration 1: Flexible covering materials recover from mechanical impact

Many of these systems are provided as 2-in-1 solutions, i.e. as pre-covered insulation materials. Products such as Arma-Chek Silver, Arma-Chek D or Arma-Chek Juna – the latter was specially developed for shipbuilding applications – can be installed in one work step, allowing significant time and cost savings. Installing these much lighter coverings also eliminates the need for support and load-bearing structures, which are often necessary when metal claddings are used. An additional benefit of the products is that they can be installed easily, directly on site, without the need for special tools. As making fitting covers is particularly time-consuming, the pre-covered insulation materials such as Arma-Chek Silver are also available as pre-fabricated elbows and T-pieces. This allows installation times to be reduced even further.

Space-saving insulation thicknesses

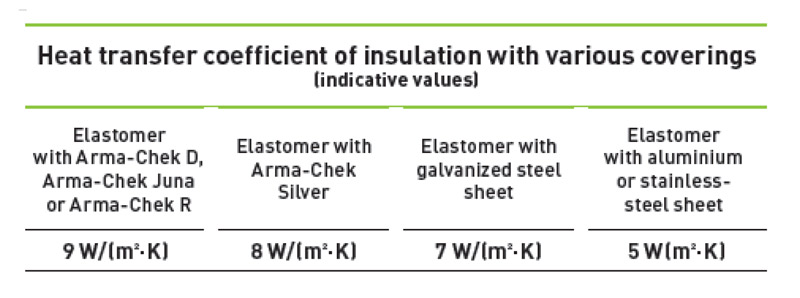

A further advantage of these pre-covered insulation materials are the thinner and therefore space-saving insulation thicknesses. The minimum insulation thickness required to prevent condensation depends not only on the humidity, line and ambient temperature, but also on the heat transfer coefficient of the insulation material. A black surface absorbs much more heat energy than a metallic cladding. This has an extremely positive effect on the insulation thickness required to prevent condensation: the higher the absorptive power, the lower the insulation thickness required for condensation control. So when using a very shiny surface the wall thickness must be greatly increased. The heat transfer coefficient of a metallic surface is almost 50 % lower than that of insulation covered with a black or grey material.

Table 1: Heat transfer coefficient of insulation with various claddings (indicative values)

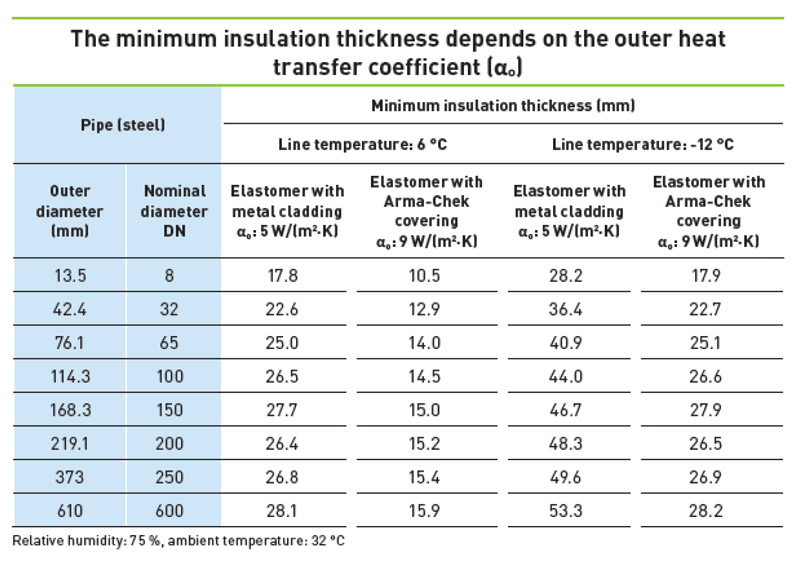

As the comparison in Table 2 shows for various line temperatures and pipe diameters, the minimum insulation thickness on metal-clad equipment sometimes has to be almost twice as high to ensure condensation control.

Table 2: The minimum insulation thickness depends on the outer heat transfer coefficient (a)

The heat transfer coefficient on the pipe or duct surface is also reduced if services are installed too close to each other or to building elements. Therefore when planning and installing pipes and ducts it is essential to ensure that there is enough space between them and that they have sufficient clearance to walls and other fixtures. Otherwise it is not only difficult to install insulation material professionally, there is also the danger of creating “build-up zones” where the air circulation (convection) needed for a sufficiently high surface temperature is prevented. In such build-up zones the heat transfer coefficient is lower, resulting in a greatly increased risk of condensation (see Illustration 2).

Figure 2: No air circulation: When build-up zones prevent convective heat transfer, the risk of condensation rises

For pipe outer diameters up to 400 mm, the minimum space between uninsulated and/or insulated pipes must be at least 100 mm and the distance to objects should be at least 200 mm. In practice, however, there is often not enough space to comply with these requirements. Due to cost pressure or a lack of knowledge, pipes are often laid too closely. This is true for both the construction and shipbuilding sector.

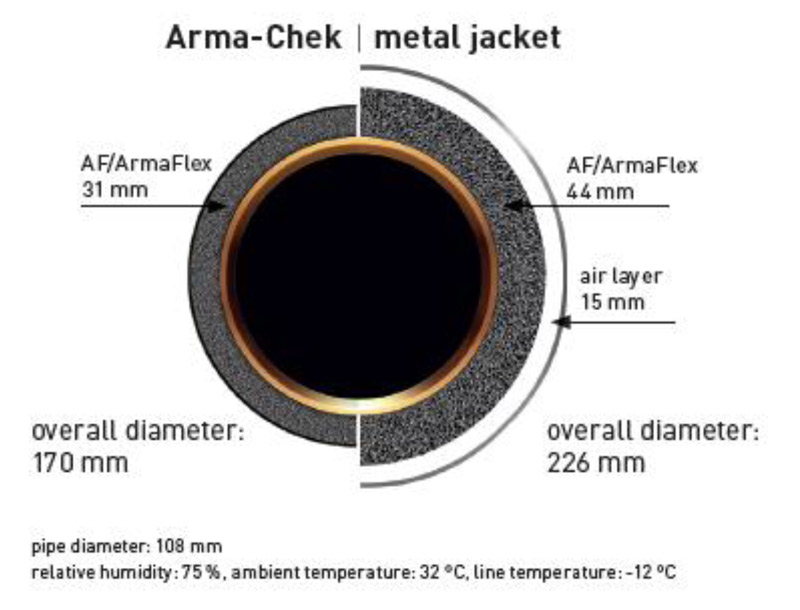

The lack of space becomes apparent at the latest when the pipes need to be clad. Here pre-covered insulation materials offer clear advantages: lower insulation thicknesses are needed to prevent condensation and there is no need to leave an air gap between the insulation and the cladding as is the case with screwed or rivetted sheet metal. Especially in tight conditions, insulators benefit from the installation advantages of the flexible 2-in-1 products.

Illustration 3: Insulation covered with Arma-Chek requires lower insulation thicknesses

Less weight, less space required

The specific benefits of pre-covered insulation materials come to the fore not only when insulating pipes, but especially in complex application areas. The main difficulty regarding a functioning

insulation system for large outdoor vessels (iced-water and cooling tanks) is the substructure. Not only the weight of the insulation and the cladding must be taken into account at the planning stage, but also wind and snow loads. Constructing substructures for the insulation of refrigeration vessels is, therefore, very complicated. In contrast, when pre-covered elastomeric insulation materials are used a substructure is generally not necessary. The much thinner and lighter material needs neither supporting nor load-bearing constructions. An additional advantage is that using Arma-Chek completely eliminates the work step in which a metal jacket is fabricated. This not only increases productivity but also leads to much lower overall costs.

Caption: When insulating vessels with pre-covered insulation materials a substructure is usually not necessary

Similar problems arise when insulating large air ducts located outdoors. If they are clad with a metal jacket, the ducts require a substructure. Here supporting constructions made of Z- or U-profiles are usually installed which are screwed or rivetted to the ducts. This is not only very time-consuming, but can also lead to acoustic problems. If the constructions are not acoustically isolated from the air ducts, whistling which occurs around blind rivets or screws can be transmitted through the duct system. Thermal bridges must also be avoided, of course. Especially outdoors, e.g. when insulating ducts for outdoor air and outgoing air on the roofs of buildings, factory pre-covered products offer great benefits. Here too, substructures are generally not needed for stability and two further work steps are eliminated: aligning the metal cladding and installing it.

Caption: It couldn’t be faster: When insulating the ducts for outdoor and outgoing air located outside 2-in-1 products allow significant time savings

Easy-to-clean surfaces for highest hygiene standards

To ensure that food and beverages are produced hygienically, this industry is one of the most heavily regulated. Pipes, ducts and vessels must be cleaned regularly. The use of pre-covered insulation materials with an easy-to-clean surface is therefore a good choice in the food industry, and also in research facilities. The high humidity resulting from intensive steam-cleaning of equipment creates optimal growth conditions for mould. In this environment, there is a particularly high risk of germs settling in the insulation of pipes, air ducts and other equipment.

If traditional open-cell insulation materials with a metal jacket are used, there is a risk of water penetrating the insulation if the cladding is not completely tight. In combination with dust and dirt particles, damp mineral fibre insulation then provides an ideal breeding ground for microbial growth. Germs can settle on the surface of pipes and ducts forming a layer of slime which may then result in a biofilm. Once a biofilm has formed, it can only be removed through thorough mechanical cleaning followed by disinfection. This means that the entire insulation and cladding material have to be renewed. The real problem, however, is that the source of bacteria and mould is often not detected because the processes take place under the metal jacket and are therefore hidden. Arma-Chek Silver and Arma-Chek Juna are manufactured on the basis of AF/Armaflex. The elastomeric insulation material has a closed-microcell structure, very low thermal conductivity and high resistance to water-vapour transmission. These properties ensure that equipment insulated with Arma-Chek has long-term protection against condensation. Because they are dust- and fibre-free materials, Armaflex products offer passive protection against micro-organisms. In addition, AF/Armaflex is equipped with antimicrobial MICROBAN® technology and provides active protection against harmful bacteria and mould.

The robust surface of the pre-covered insulation materials is highly resistant to chemicals. This resistance to a number of different acids, alkalis, salt solutions, hydrocarbons, alcohols, etc. not only

provides equipment with tough protection against aggressive ambient conditions, but also means that disinfectants can be used for cleaning, for example.

Protection against corrosion under insulation

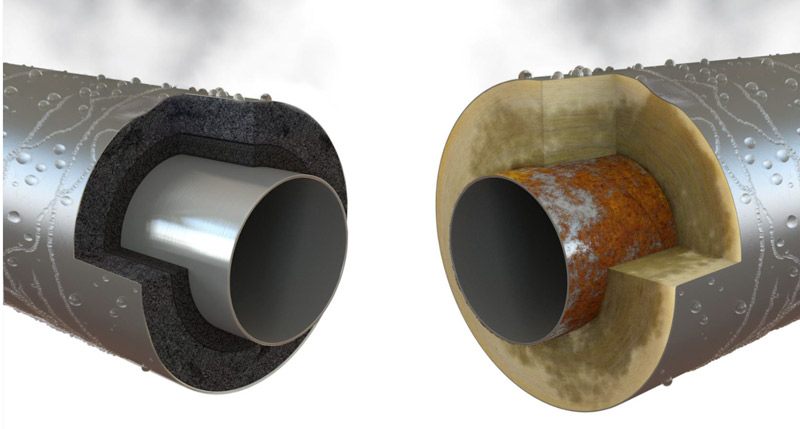

All these flexible 2-in-1 systems provide good protection against corrosion under insulation (CUI). Because the covering is glued directly to the insulation, any risk of water ingress is ruled out. If the cladding system is not completely tight – and with metal jackets it is never completely possible to ensure that it is – water can penetrate the insulation. Moisture not only leads to a drastic reduction in the thermal properties of the insulation material, significant corrosion damage can occur under the insulation, resulting in extensive renovation work and high costs. As the term “corrosion under insulation” aptly describes, the processes take place underneath the insulation and its cladding and often remain undetected for a long time. A clear advantage of flexible covering systems are the direct connections to the adjoining insulation which rule out the risk of water ingress because where there are no seams or beads, neither moisture nor germs can penetrate the insulation. As an application comparison test has shown, pipework insulated with Arma-Chek is much better protected against corrosion than metal-clad equipment.

Illustration 4: As an independent study shows, ArmaFlex insulation materials minimise the risk of corrosion under insulation. Open-cell insulation materials, on the other hand, are not protected against moisture absorption and present a higher CUI risk.

Illustration 4: As an independent study shows, ArmaFlex insulation materials minimise the risk of corrosion under insulation. Open-cell insulation materials, on the other hand, are not protected against moisture absorption and present a higher CUI risk.

Summary

Compared to sheet metal claddings, pre-covered elastomeric insulation materials are much lighter. This means that mounting structures are not usually necessary for larger equipment, which has a positive impact on the costs. The materials can be installed directly on site in one work step, allowing further significant savings in terms of time and costs. Some of the systems are especially suitable for hygiene-critical applications: their surfaces are particularly easy to clean and if there are no seams or beads, there is nowhere for germs to settle. Elastomeric materials also provide good protection against corrosion under insulation. Insulation manufacturers offer special application training courses for the successful installation of their systems.

Weitere Illustrationen:

(Lead): Caption: Ideal combination of attractive metal appearance and fast and space-saving installation

Caption: Unlike traditional insulation materials and claddings, the flexible 2-in-1 systems can be installed in a single work step and allow significant space savings

All photos and illustrations: ©Armacell